MOULD WATER JACKET

What is Mould Water Jacket?

It is a machine to make pellets by converting powdered raw materials into spherical or melodic form.

It is widely used in the field of powders, bringing solidification fuel, uniformity of materials, dust reduction effect, transportation cost reduction effect, and volume reduction effect.

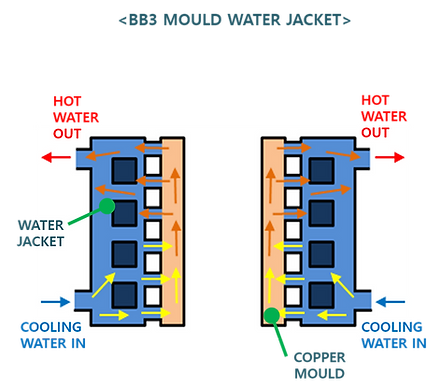

Mould Water Jacket Type

● Water circulated out of the copper mould

● Water circulated inner of the copper mould

● The inner channel and the water jacket channel inside the mould are assembled correctly

Mould Water Jacket Design Considerations

Which type of jacket is best?

The way the water circulates depends on the mould. In generaThe way the water circulates depends on the mould. In general copper mould, water circulates to the outside of the mould and cools it, and the type having the inner channel in the copper mould itself cools by injecting water into the mould by matching the inner channel of the water jacket with the inner channel of the mould.l copper mould, water circulates to the outside of the mould and cools it, and the type having the inner channel in the copper mould itself cools by injecting water into the mould by matching the inner channel of the water jacket with the inner channel of the mould.

Have you considered moving speed?

Inside the mould water jacket there is a guide to the mould, which is curved. The cInside the mould water jacket there is a guide to the mould, which is curved.

The center of curvature of the front and back of the guide coincides with the center of the mould, which is ideally positioned to coincide with the center of curvature radius of the dummy bar so that the billet exiting the mould can be flexibly extracted.enter of curvature of the front and back of the guide coincides with the center of the mould, which is ideally positioned to coincide with the center of curvature radius of the dummy bar so that the billet exiting the mould can be flexibly extracted.

How much cooling evenly?

The quality of the mould water jacket depends on how well it cools the mould, thus improving the quality of the billets in it. If the cooling is uneven, it will not be partially cooled or only one part will be rapidly cooled, so the quality inside the billet can not be guaranteed. Therefore, the gap between the mould and the water jacket is maintained to maintain a uniform 3.5mm cooling design.

Is the mould water jacket compatible with the wear of the mould?

The more moulds are used depending on the work, the more they are predicted, and the smaller the size change of the mould is predicted.

Is it possible to design professionally with precise processing?

Holes dug in and out of the jacket are for smooth circulation of the coolant, and when the machining is poor, black out phenomenon may occur because the cooling is not performed properly and water is drained out. Accurate assembly of the channel between the mould and the water jacket is required and there are more than 150 assembly bolts. This requires precise professional design and ultra precision machining. Accurate sealing is also necessary to prevent water leakage to the outside.

▲ GAGE to check the gap between

mould and water jacket

▲ Integrated O-ring for sealing

Manufacturing Solution by Samshin

Site sketch and Drawing design

Design by sketching the actual item used in the field. Consideration should be given to the deformation caused by the use of existing products, and improvements such as problems in use shall be reflected in the design.

The mould water jacket is manufactured by cutting steel sheet because the unit price is high and the surface of the part that cannot be processed is rough in appearance when manufacturing casting. Samshin presents the following management solutions in production.

Manufacturing

Waterjet cutting

Straightening

Stress relief

Precision machining

● Waterjet cutting: mould water jacket is made of STAINLESS more than 30T, so the cutting surface is uneven when

cutting gas and laser.

● Straightening: In order to prevent welding deformation caused by rib reinforcement welding on the outside, welding

is performed after fixing the support and calibration is completed after welding is completed.

● Stress relief: Residual stress reduction technology (VSR) is introduced to reduce the partially operated residual stress

and improve quality and life.

● Precision Machining: The ultra-precise machining is performed with the latest machinery, and the error range is ± 0

Inspection

When, the mould water jacket is manufactured, quality control checks are carried out. Samshin presents the following management solutions on prosecutor's office

Perpendicularity

Dimensional Measurement

Assembly

Inspection report

● Perpendicularity: Precision bending is done by hydraulic bending, and jig for self-gauge is manufactured to check

right angle.

● Dimensional Measurement: Check the drawing dimensions and check the overall dimensions.

● Assembly: In order to comply with GAP 3.5mm of mould and water jacket housing, GAP check is required by making

its own gauge.

● Issuance of Inspection Report: Material Sheet, Dimensional Inspection Report, Visual Inspection Report, etc. Issue the required inspection report.

The more moulds are used depending on the work, the more they are predicted, and the smaller the size change of the mould is predicted.

Is the mould water jacket compatible with the wear of the mould?

Acid cleaning

Packaging

Palleting

Heat treatment result

● Acid cleaning: mould water jacket is made of stainless steel, and no painting is required, but metal oxide on the surface

is removed by Acid cleaning. This process, which removes the welding soot and surface stains, allows you to check

again for material defects.

● Packaging: Use an internal shock absorber to prevent damage to the product, and use a rustproof vinyl to prevent the

ingress of moisture in the product.

● Palleting: The product manufactures a sealed box to prevent moisture, dust shock and theft from the outside.

● Wood Heat Treatment Result: Heat-treated wood is used for rapid passage to agricultural and livestock quarantine.

Installation

In order to make the most of the right product, it is important to install it properly. Depending on how the product is installed on site, it is the first step in extending the life of the equipment and reducing downtime due to maintenance. Samshin offers the following management solutions during the installation process:

Precise assembly

If the assembly of the water jacket and the oscillator connected is not correct, the oscillation mark generated when the product comes out will appear uneven. As this affects the internal quality of the product, accurate assembly of the surrounding equipment and the water jacket is essential.

Coolant temperature management and site-specific coolant treatment

The proper temperature change of cooling water is 6 ℃ ~ 8 ℃. Improper temperature control will result in poor cooling and uneven product quality. Cooling water that has passed through hot water at up to 1000 ° C is treated and reused in two ways. The first is an open (direct) cooling method in which the coolant that has passed through the waste water is mixed with other unused cold coolant, filtered through a filter, and reused. The second method is indirect cooling, in which the coolant pipe is indirectly absorbed by placing the coolant pipe alongside other pipes with relatively cold liquid.

Field Engineer

If the manufacturer's technician installs it by hand, he can quickly determine what to look for and what errors. It can also provide equipment maintenance information to field maintenance workers. Many errors can be reduced if field technicians identify and supervise installation work.

Specification

※ Detailed specification of Mould water jacket can be adjusted according to customer's requirement

※ BB1, BB2, BB3 mix match available

Why should you choose Samshin?

From design to manufacturing

We have many experts in each field, and can guide you through all stages from product design to production management

Perfect collaboration system

We provide a complete system through cooperation with various specialized companies for a long time. We are growing together with our partners through quality improvement support based on mutual trust. It is possible not only to provide a single item but also to supply equipment to the manufacturing process.

Continuous technology development

We will continuously develop technology with company-affiliated research institute and launch new products using high value-added products and core technologies. In addition, it holds numerous industrial machinery patents through continuous and creative research and development.

Quality is the best value

Our unlimited enthusiasm for quality control from production management to delivery date and our unwavering commitment to satisfy our customers' needs by developing differentiated new products through international certification acquisition and capacity building

Customer satisfaction

Through product development, zero defect production, perfect quality control and customer support system through own technology, AS repair can be done until customer is satisfied. It is possible to repair the product even though it is not a product of Samshin.

Vietnam corporation

In February 2016, SamShin of Vietnam was launched, and in March 2019, Vietnam plant was built. A total of 30 employees, including two Korean executives and a local engineer, are stationed in Vietnam's manufacturing plants.

Pictures of Vietnam Samshin

Delivery Performance of Mould water jacket

Mould Water Jacket Manufacturing

2018, 2019 POSCO SS-VINA