MIXER

믹서의 정의

2종류 이상의 분말 또는 가용성 액체를 혼합하기 위한

혼합기의 일종이다.

블레이드의 회전으로 균등질의 원료를 혼합하는 설비며,

블레이드에 의하여 전단력으로 난류 및 분자 확산보다 더 큰 강제 대류를 발생 시킨다.

RIBON MIXER

적용분야

RIBBON-type rotating body is installed in the mixing chamber, which is relatively inexpensive and most commonly used type. It is widely used in the chemical, food, and pharmaceutical industries.

Advantages

● Uniform and stable mixing

● Less noise and vibration

● Stable, easy to operation, maintenance

● No overflow due to overload

How it works

Design two RIBBON WHEELs with different movement directions to cross each other.

While the PITCH on the outside is made larger and the PITCH on the inside is made smaller, the mixing proceeds by an up and down motion opposite to the complicated flow by RIBBON.

Specification

PLOUGH MIXER

Application

It is mainly used in chemicals, foods, medicines such as dry powder, wet sludge mixing, wet granulation. It is also used to make abrasives such as brake linings.

It is suitable for adhesive or deadlock additive mixture, mixing powders + liquids, powders + trace additives and complex processing.

Advantages

● Short mixing time

● High quality for mixing raw materials with large particle size and specific gravity

difference

● Excellent effect in mixing small amounts of additives between powders

● Almost no lumping of raw materials when using high speed chopper

● The material that needs to be mixed and reacted is very suitable by a massage effect

● Shredding and mixing with high speed chipper function

How it works

The PLOUGH-shaped blade forms a fluidized bed at a constant rotational speed and moves the mixture from side to side with mixing.

Dispersion and milling effect can be achieved by using high speed chopper when mixing small amount of additive or liquid addition.

After completion of mixing, discharge is carried out by the outlet on the center, and the outer wing pushes the raw material inward, so it can be discharged into the raw material in the area without the outlet.

Specification

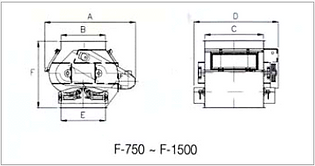

Drawing

PADDLE MIXER

Application

It is mainly used when mixing molasses feed and cereal products, and is widely used in food, grain, feed, chemical, castings, ceramics, dyes and pollution prevention industries. It can be used for mixing powder + liquid, thin dough + dry powder, high viscosity, and semi-liquid state.

Advantages

● Easy to input and discharge, no separation during discharge

● Mix uniformly because raw materials are distributed and moved radially by the dynamic structure of paddle

● As rotating shaft is low speed, there is no damage to the raw materials because no impact and shear force are generated.

● Since the mixing is carried out within a short time, the operation cost and productivity are maximized. Also maintenance cost is low.

How it works

Several ARMs are fixed to two parallel MAIN SHAFTs, each with a PADDLE.

This paddle is designed to overlap each other. Power is transmitted so that both axes rotate at constant speed in the opposite direction. PADDEL pumps up the raw materials and mixes them by rotational force.

Specification

Minimum mixing time between materials

Application of Mixer

Mixer is used throughout lots of industrial area for mixing.

The most common use is for mixing foods or drugs, but basically used for mixing raw materials in plant industries.

Basic specifications should be customized after consultation with the properties and site conditions.

Mixer Design Considerations

You should consider the type and output of the mixer by identifying which materials to mix, the density and viscosity of the material.

What materials to mix?

The most inexpensive and common type is RIBBON TYPE, but SHOVEL TYPE can be considered if the particle size and specific gravity are large, and PADDLE TYPE can be considered in the high viscosity and semi-liquid state.

What type of BLADE will you use?

How much capacity do you want?

Depending on the desired capacity, design should be made taking into account the size of the shaft, the number of blades, the size of the cylinder, and the output

The type and location of the BLADE are determined by process requirements. The role of BLADE differs depending on the position in which the transport is to be carried out and the mixing is performed. Once the BLADE has been determined, the torque and bending moment must be calculated to design the weight, torque, and load of the shaft.

Consider shaft length and position of BLADE

Have you found the optimal mixing efficiency?

It is important to disperse and uniformly mix the raw materials in consideration of grasp of the material, grasp of damage that may occur in mixing, reaction in the material mixing process, and aggregation of the raw materials.

Delivery Performance of Rotary Kiln

POWDER RAW MATERIAL MIXING PLANT

1995, RIST

POSCO #3 FINEX MIXER

2013, POSCO E&C

POSCO #3 FINEX PLOUGHSHARE MIXER

2013, POSCO E&C

POSCO Pohang Dongchon Research Station Large Capacity Coal Blend Ribbon mixer

2015, POSCO

POSCO PosLX ME CO PADDLE MIXER

2018, POSCO